The mechanical workshop at IAU university offers a wide range of services that include the following operations:

- Three-dimensional scanning to capture the entire geometry of part surfaces and features with metrology accuracy.

-

Operations done using CNC and manual lathe machines:

- Facing, Form/Taper/Contour Turning, Chamfering, Cutoff/parting, Boring, Threading, Drilling operations.

- Operations done using 5-axis CNC and 3-axis manual milling machines:

- Machining of complex geometry using 5-axis vertical mill machine

- Face, Plain / Snab, Angular, End Millings

- Cutting of metallic & non-metallic parts.

- Drilling at just about any angle using the radial drill press featuring variable table swing and pivoting heads.

- Sheet metal bending to any predetermined bends.

- Shearing sheet and plate material, most commonly sheet metal.

- Rolling of sheet metal at various radii.

- Pipe bending

- Notching of sheet metal

- Surface grinding

- Oxy acetylene welding & cutting

- Stick welding

- TIG pulse welding

- Spot and projection welding

- Plasma cutting

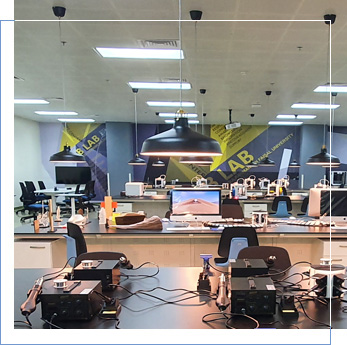

In addition, the FabLab at IAU university provides access to a wide range of services, which include the following operations:

- 3d-printing and CAD modeling

- Laser cutter machine

- 5-axis CNC milling machine

- Soldering station

- PCB engraver machine

- PC station

- A variety of hand-tools such as screw drivers, battery-powered drills, manual cutting saw, etc